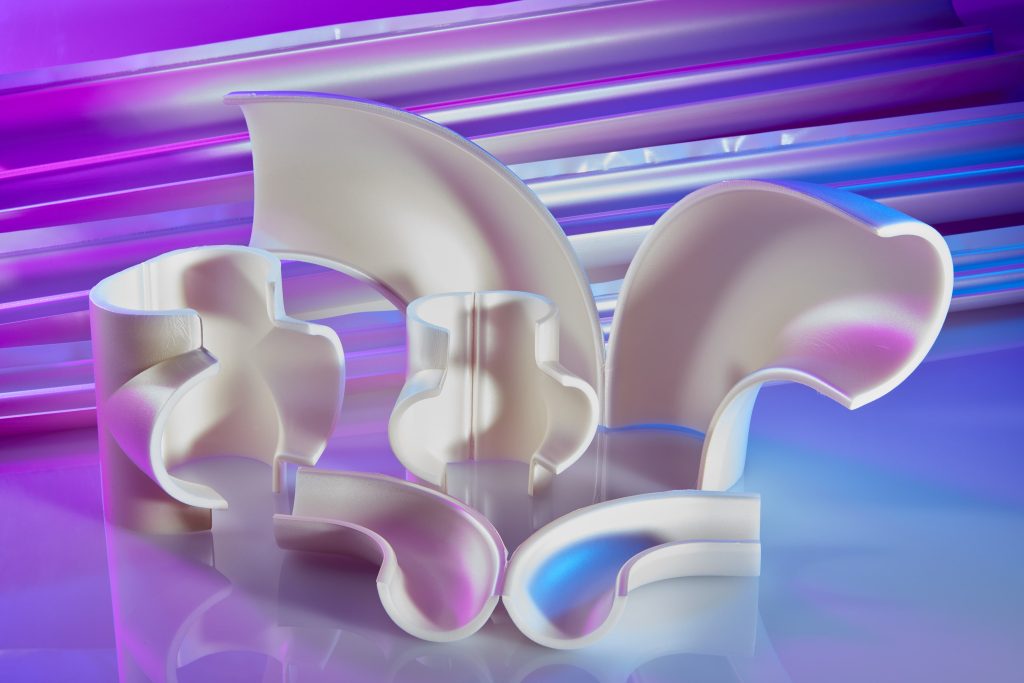

T-FIT® Hygiene: Insulation tailored for FMCG production processes

T-FIT® Hygiene insulation is the leading choice for aseptic production areas in food and beverage, dairy and personal care manufacturing environments due to its fire-retardant properties and resistance to moisture and fungal growth.

Features

Advanced Insulation Technology

T-FIT® insulation inherits the unique properties built into Zotefoams closed cell foams. Particulate-, dust-, fibre-free and almost zero VOCs, inherently hydrophobic and highly resistant to fungal and mould growth providing exceptionally hygienic performance in any environment.

Wide Temperature Range

Suitable for both chilled and hot processing applications with an operating range of -80°C to +145°C. Ideally suited to FMCG production processes that regularly cycle between low and high temperatures.

Easy Installation & Maintenance

Fast, tool-free installation — plus a long maintenance-free service life — pipe insulation components are easy to open and close for inspection, and are available in 12.7mm and 6.35mm thicknesses, depending on specification

Workforce Friendly

No harmful chemicals or particles are given off during installation or during the products’ extended, in-use lifespan. All T-FIT® pipe insulation products provide excellent protection from hot pipework for clothing, skin and equipment.

Leading Fire Safety Credentials

Excellent flammability credentials tested to Euroclass EN13501-1, achieving classification to B-S1-D0. T-FIT® Hygiene delivers one of the lowest flame, smoke and toxicity rating of any polymer/elastomer insulating product.

Environmentally Friendly

Market leading durability with 10-year refit intervals. Once installed, T-FIT is there to stay. No more regular ‘stop-remove-dispose’ refits with all the associated waste. Providing a low lifetime cost of ownership.

Hygienic pipe insulation specifications

This information is given to the best of our knowledge and should be considered as guidance only for selecting a suitable material for your application.

| Property | Test Standard | Typical Value |

|---|---|---|

| Material | Manufactured from an FDA-compliant resin | |

| Service Temperature | See Notes in Datasheet | -80°C to + 145°C (-112°F to +293 °F) |

| Thermal Conductivity | ISO 8301 | |

| Mean temperature of 25 °C (77 °F) | 0.034 W/m.K (0.24 Btu.in/h.ft2 °F) | |

| Mean temperature of 50 °C (122 °F) | 0.037 W/m.K (0.26 Btu.in/h.ft2 °F) | |

| Mean temperature of 80 °C (176°F) | 0.040 W/m.K (0.28 Btu.in/h.ft2 °F) | |

| Fire Certification | ||

| Euroclass | EN13501-1 | B-s1, d0 |

Case Studies

See real-world examples of how T-FIT® Hygiene insulation has transformed manufacturing environments.

Demonstrating Durability: Testing T-FIT® Insulation in Low-Temperature and Cryogenic Applications

Transforming Energy Efficiency at Meantime Brewing

Reducing the carbon footprint of pharma manufacturing with high-performance insulation for cleanrooms and utility areas

T-FIT® Insulation Takes Mackie’s Closer to ‘Britain’s Greenest Business’ Goal

Certified & Award Winning

Certified to meet stringent international standards, T-FIT provides reliable pipe insulation solutions that cater to the needs of diverse industries. Our company’s award-winning status underscores our commitment to excellence and sustainability.

Achieve the lowest Total Cost of Ownership of any high-performance cleanroom insulation system

Installation Guides

Our easy-to-follow guides are available to walk you through the installation process.

Research

For in-depth product testing information, competitor reviews, detailed reports and analyses demonstrating the exceptional performance and reliability of T-FIT Hygiene insulation in various applications.

How long does T-FIT® last?

T-FIT insulation products are designed for long-term performance and can last over 20 years, depending on the application and maintenance conditions.

What thickness is T-FIT® supplied in?

T-FIT® insulation has an ultra slim profile, making it ideal for complex pipe runs. It can be supplied in different thicknesses, depending on the specific product variant and application. The T-FIT Hygiene insulation, for example, is available in 6.35mm and 12.7mm thicknesses.

Can T-FIT Insulation help prevent condensation?

Yes, T-FIT Insulation is highly effective at preventing condensation. Its hydrophobic properties ensure that surfaces remain dry, significantly reducing the risk of water damage and microbial growth. This helps maintain a safe, dry, and hygienic environment, crucial for food and beverage operations.

Why is the outgassing level of T-FIT® products so low?

T-FIT products are manufactured using high-quality, closed-cell foam materials that significantly reduce the risk of outgassing. This ensures that they maintain a clean environment, critical for sensitive applications such as semiconductor and biopharma industries.

Can T-FIT® promote the development of fungal growth?

No, T-FIT insulation is resistant to microbial and fungal growth, thanks to its closed-cell structure and material composition.

What is the max service temperature for T-FIT®?

The maximum service temperature for T-FIT insulation products can be as high as 160°C (320°F), depending on the specific product and application requirements.

What is the lowest service temperature for T-FIT®?

The lowest service temperature for T-FIT insulation products can be as low as -80°C (-112°F), depending on the specific product and application requirements.

What line temperature would be after insulated with T-FIT®?

The line temperature after insulation with T-FIT products depends on the specific application and environmental conditions. However, T-FIT insulation is designed to maintain stable temperatures, significantly reducing heat loss and energy consumption.

Does T-FIT® need an outer cladding?

No, T-FIT insulation does not require an outer cladding for most applications as it is inherently durable and resistant to external damage. However, cladding can be provided for additional protection if required.

Is T-FIT® certified by any third-party certification?

Yes, T-FIT insulation products are certified by various third-party organizations for performance, safety, and compliance with industry standards.

Is T-FIT® more expensive than traditional materials such as Wool or Rubber?

While the initial cost of T-FIT insulation might be higher than more traditionally used materials, the lifespan of the product is far superior. Meaning the long-term savings in energy costs, maintenance, and durability make it a more cost-effective solution over the product’s lifespan.

What is crosslinking, and why is it important?

Crosslinking is a process where polymer chains are chemically bonded to form a three-dimensional network. This enhances the material’s mechanical properties, making it more durable, stable, and resistant to heat and chemicals. For T-FIT products, crosslinking ensures superior performance and longevity in demanding industrial environments.

What is the thermal conductivity of T-FIT®?

The thermal conductivity of T-FIT insulation products is very low. At a mean temperature of 0 °C (32 °F), the thermal conductivity is 0.0314 W/m.K (0.22 Btu.in/h.ft2 °F), providing excellent thermal insulation performance.

What is PVDF?

PVDF (Polyvinylidene fluoride) is a high-performance thermoplastic known for its excellent chemical resistance, mechanical strength, and stability. It is often used in applications requiring high purity and resistance to aggressive chemicals.

What is the difference between open and closed cell insulation?

Closed cell insulation has tightly packed cells that provide better thermal resistance, moisture barrier, and structural integrity compared to open cell insulation, which has interconnected cells that are less effective at blocking heat and moisture.

Is T-FIT® closed cell?

Yes, T-FIT insulation products are made from closed-cell foam, which provides superior thermal insulation, moisture resistance, and mechanical strength.