Introduction

In clean manufacturing environments—such as cleanrooms, pharmaceutical facilities, and food production plants—maintaining a sterile and contaminant-free space is essential. One of the most significant threats to these controlled settings is microbial contamination caused by fungal growth. The solution? Insulation materials designed to resist fungi and prevent mould growth.

Understanding the Threat of Fungal Growth

Fungi may seem like a minor issue, but in clean manufacturing environments, their impact can be devastating:

- Product Contamination: Mould and fungi can compromise the cleanliness of manufacturing areas, leading to contaminated products and costly recalls.

- Cleanroom Compliance Risks: Mould growth can jeopardize a facility’s compliance with strict regulatory standards, including cGMP, risking fines and operational shutdowns.

- Health Hazards: Airborne fungal spores can harm workers’ health and the quality of pharmaceutical or food products.

What Makes Insulation Vulnerable?

Many insulation materials have surfaces that trap debris, moisture, or nutrients, creating an ideal breeding ground for fungal growth. In warm, humid conditions—often present in food production facilities—fungi can quickly proliferate, threatening the integrity of the clean environment.

T-FIT: The Proven Solution for Fungus Resistance

T-FIT insulation is engineered to eliminate the risk of fungal growth, ensuring cleanliness and compliance. Here’s how it sets itself apart:

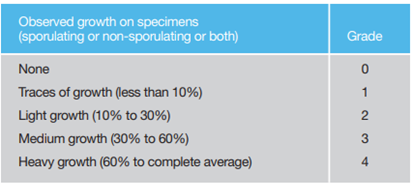

ASTM G21 Testing Excellence: T-FIT insulation has been tested for fungus resistance. The ASTM G21 standard exposes materials to five fungal species in high humidity (85%+) and warm temperatures (28-30°C) over 28 days. T-FIT consistently scores a mould growth rating of zero, indicating no visible fungal growth.

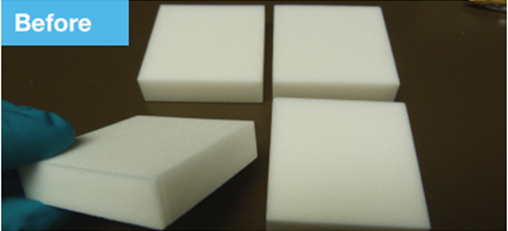

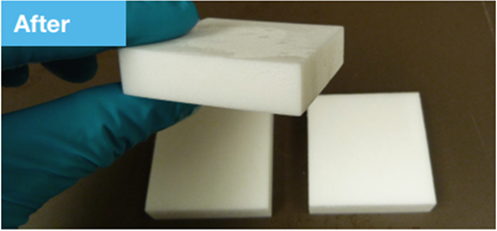

The images above show the foam samples before and after the test; as one can see the samples look as good as new, even after 28-days exposure to a variety of fungal spores in high humidity.

Smooth, Sealed Surfaces: Unlike porous insulation materials, T-FIT Clean insulation has a smooth, non-porous surface. This design prevents the accumulation of nutrients, debris, and moisture that fungi need to thrive.

Durability in High-Risk Environments: Even in challenging conditions, T-FIT insulation maintains its integrity, making it an ideal choice for environments with stringent cleanliness requirements.

Why Fungus Resistance Matters

Choosing fungus-resistant insulation isn’t just about maintaining a clean facility—it’s about ensuring operational efficiency and compliance with industry standards.

Controlling fungal growth protects:

• Product Integrity: Prevents costly contamination and production delays.

• Compliance: Reduces the risk of failing inspections and ensures adherence to cGMP and other industry guidelines.

• Workplace Health: Minimises the risks of mould-related health issues for employees.

Conclusion

In environments where cleanliness and sterility are paramount, fungal growth is a risk you cannot afford to ignore. By choosing T-FIT insulation, you gain a trusted partner in maintaining a contaminant-free space. With its proven fungus resistance, smooth surface, and exceptional performance in demanding conditions, T-FIT insulation ensures your facility stays clean, compliant, and efficient.

Don’t let mould compromise your operations. Choose insulation that works as hard as you do—choose T-FIT.