The Hidden Danger of Moisture in Insulation: What You Need to Know

Published

December 2, 2024

Introduction

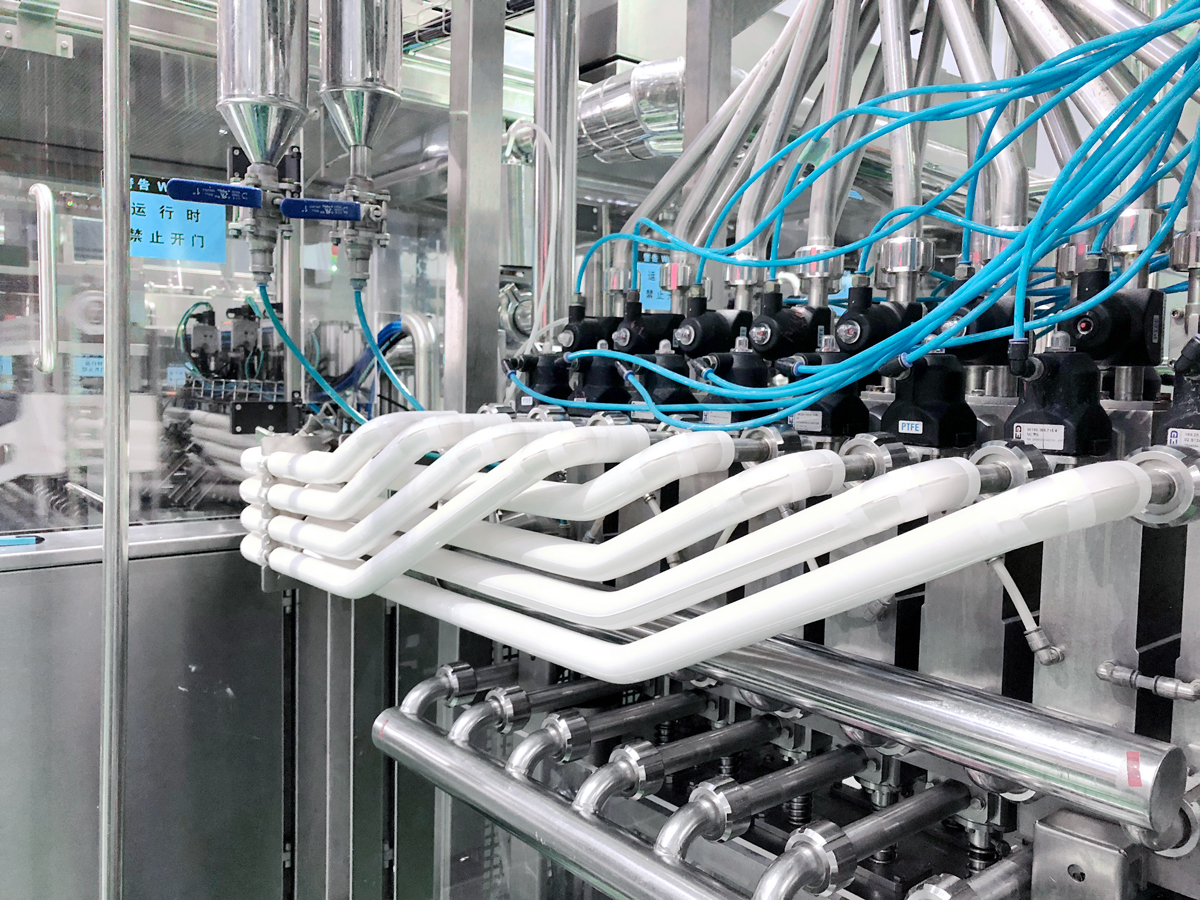

In controlled environments like cleanrooms, food and beverage facilities, and pharmaceutical manufacturing, maintaining optimal insulation performance is critical. However, one often-overlooked factor that can significantly undermine insulation efficiency is moisture penetration.

It has been shown that just 4% water absorption by insulation can lead to a 70% reduction in its thermal performance. Furthermore, a staggering 98% of insulation failures are due to water absorption/wicking. Failed or poor-performing insulation can lead to injury, increased energy use and product contamination.

This silent invader can lead to costly and potentially dangerous consequences, making moisture resistance a non-negotiable feature for high-performance insulation.

The Problem with Moisture

Moisture in insulation poses serious risks that go beyond reduced thermal efficiency. Here’s why it matters:

- Increased Thermal Conductivity: Water conducts heat about 20 times better than air. When moisture seeps into insulation materials, it raises the thermal conductivity, reducing the material’s ability to maintain desired temperatures. This compromises energy efficiency and increases operational costs.

- Corrosion Under Insulation (CUI): Trapped moisture can accelerate the corrosion of underlying pipe systems, leading to equipment failures and safety hazards.

- Bacterial Growth: Damp insulation creates a breeding ground for bacteria and mould, which can contaminate clean environments and jeopardize product safety.

- Structural Strain: As insulation absorbs moisture, its mass increases, putting additional pressure on pipe systems and structural components.

How T-FIT Insulation Addresses Moisture Issues

T-FIT insulation is designed to combat these challenges with advanced material technology that prevents moisture penetration. Here’s how it works:

- Closed-Cell Foam Structure: Unlike traditional insulation that relies on external cladding, T-FIT insulation uses closed-cell foam. This material inherently resists water absorption, maintaining its thermal properties and durability over time.

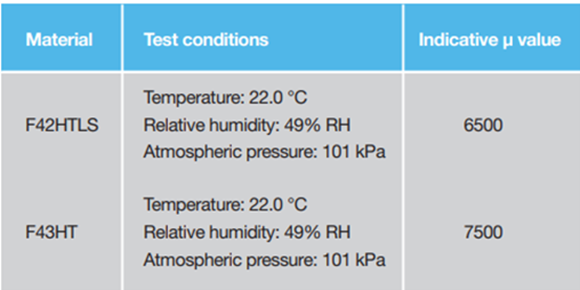

- High Water Vapour Diffusion Resistance: T-FIT boasts exceptional water vapour diffusion resistance (µ values). For example, a 6.35mm layer of T-FIT insulation at 23°C has the same resistance to water vapour transmission as 40 meters of still air at the same temperature. This barrier ensures that moisture stays out, even in humid conditions.

Why It Matters

Moisture in insulation doesn’t just lead to technical issues—it can also cause significant financial and operational setbacks. Energy losses, contamination risks, and the potential for equipment damage highlight the critical importance of selecting an insulation material that offers consistent moisture resistance.

While traditional insulation with aluminium cladding may claim high water vapour resistance, these properties depend on the cladding remaining intact. Any damage to the cladding can drastically reduce resistance, allowing penetration and absorption of moisture, and compromising performance over time. In contrast, T-FIT insulation’s closed-cell foam structure provides inherent moisture resistance that remains effective even under challenging conditions.

This durable design not only protects against moisture ingress but also ensures long-term reliability, making T-FIT a dependable choice for demanding environments. By prioritising moisture-resistant insulation like T-FIT, you safeguard your equipment, maintain product integrity, and achieve lasting cost efficiencies.