Demonstrating Durability: Testing T-FIT® Insulation in Low-Temperature and Cryogenic Applications

Published

June 13, 2024

Sectors

Products

A two year insulation study conducted at Zotefoams’ manufacturing facility in Croydon.

Context & Applications:

The necessity for maintaining low sub-0°C or cryogenic (below -100°C) temperatures is critical in various fields, including quantum computers, the Large Hadron Collider, and the logistics for some vaccines. These applications cannot afford failures due to overheating or loss of efficacy because of breached ultra-cold chain parameters, highlighting the essential role of insulation.

A common feature of many low-temperature processes is the periodic return to ambient or higher temperatures, creating potential thermal shock. Traditional insulation materials like elastomers can quickly become brittle and degrade under such conditions, eroding their insulative performance.

As low-temperature and cryogenic processes become more prevalent, Zotefoams sought to test the performance of ZOTEK® F in the form of T-FIT® Hygiene Pipe Insulation in a typically demanding industrial application under thermal shock conditions to validate the exceptional durability and performance of its material.

Experiment & Results:

Zotefoams’ unique process – whereby extruded polymers are infused with nitrogen gas at pressure of up to 675bar – provides both the unique properties of ZOTEK F material, and the perfect testing ground.

T-FIT Hygiene Insulation, in the form of tubes with a thickness of just 18mm, was applied to straight pipe runs in an outdoor liquid nitrogen compound at Zotefoams’ manufacturing facility in Croydon, UK. Pipe temperatures typically oscillate six to seven times per day, in a range between typical ambient of 10°C and lows of -100°C, although the lowest temperature recorded during the test was -150°C. Temperature changes are rapid, subjecting the insulation to repeated thermal shock.

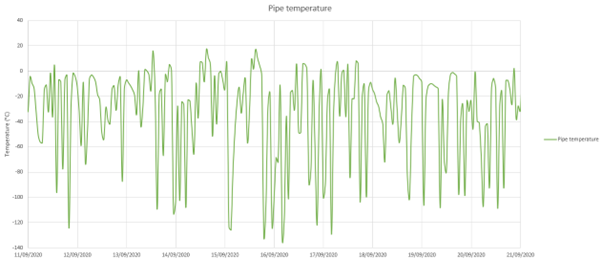

Pipe temperature over a typical ten-day period was recorded as follows:

We can see the highest pipe temperature was 20°C and the lowest -140°C, with, on average, six or more rapid changes/day.

The image demonstrate the performance of the insulation in preventing ice build-up, with straight pipe runs (top, horizontal and left, vertical) completely free of ice; by contrast the elbows, which were not insulated, show a significant build-up.

The material was left in situ for two years, equivalent to 100 weeks of 24/7 production following the patterns illustrated above. On inspection, and despite having been subjected to repeated thermal shock, the material showed no signs of degradation: it remained pliable, with no cracking, embrittlement, or surface damage.

Conclusion:

This 2-year study serves to further demonstrate the credentials of ZOTEK F as an outstanding insulation material. Zotefoams is unique in its ability to produce foams from high-performance PVDF polymers using temperature, pressure and nitrogen borrowed from the atmosphere. This process does not involve blowing agents, and additives such as fire retardants or UV stabilisers are not required, as such properties are inherent to the PVDF polymer, resulting in an extraordinarily pure, safe and high-performing insulation material.